Light Slack Wax: Applications in the Textile Industry, Specifications, and More

In the world of industrial waxes, Light Slack Wax shines as a versatile and indispensable substance, especially in the textile industry. Its unique properties and applications make it a crucial ingredient in various processes, from fabric finishing to yarn lubrication. Join us as we embark on an illuminating journey through the world of light slack wax, uncovering its uses, specifications, and the invaluable role it plays in the textile industry. With Paraffin Co. as our trusted supplier in Dubai, we’ll delve deep into the intricacies of light slack wax, shedding light on its importance and potential.

Light Slack Wax: Composition and Properties

-

Composition

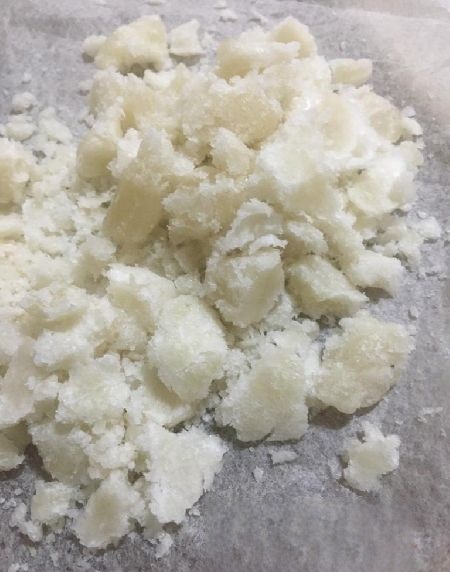

Light slack wax is a semi-solid residue obtained during the solvent dewaxing process in petroleum refining. It consists primarily of saturated hydrocarbons, including paraffins and microcrystalline wax, with a relatively low melting point and viscosity compared to other waxes.

-

Properties

- Low Melting Point: Light slack wax exhibits a lower melting point compared to other waxes, making it suitable for various applications where a lower viscosity is desirable.

- High Purity: It is typically refined to high levels of purity during the manufacturing process, ensuring minimal impurities and contaminants.

- Good Lubricating Properties: Light slack wax offers excellent lubricating properties, making it ideal for use as a lubricant in textile processing and other industrial applications.

- Compatibility: It is compatible with a wide range of materials and additives, allowing for easy incorporation into various formulations and processes.

Uses and Applications of Light Slack Wax in the Textile Industry

-

Fabric Finishing

Light slack wax is used in fabric finishing processes to impart smoothness, softness, and wrinkle resistance to textiles. It is applied as a finishing agent or additive in fabric softeners, helping to enhance the overall texture and appearance of fabrics.

-

Yarn Lubrication

In the spinning and weaving processes, light slack wax serves as a lubricant for yarns, reducing friction and improving yarn handling and processing. It helps prevent yarn breakage and fiber damage, resulting in smoother and more efficient production processes.

-

Warp Sizing

Light slack wax is employed in warp sizing formulations to coat yarns and improve their strength, smoothness, and abrasion resistance. It enhances the performance of sizing agents, ensuring uniform and consistent yarn sizing for weaving operations.

-

Dyeing and Printing

In dyeing and printing applications, light slack wax is used as a levelling agent and dye carrier, facilitating the uniform distribution of dyes and pigments on textile substrates. It helps achieve vibrant and even coloration, enhancing the quality and appearance of dyed and printed fabrics.

Specifications of Light Slack Wax

- Melting Point: Typically ranging from 50°C to 70°C, depending on the refining process and desired application.

- Oil Content: Light slack wax may contain varying levels of oil content, typically between 5% to 15%, which influences its viscosity and lubricating properties.

- Color: It is usually white to light yellow in color, with a clean and uniform appearance indicative of its high purity.

Paraffin Co: Your Trusted Supplier for Light Slack Wax

Uses and Applications of Light Slack Wax in the Textile Industry, Paraffin Co. stands as a reliable supplier of high-quality light slack wax in Dubai, offering customized solutions tailored to the specific requirements of the textile industry. With a commitment to quality, consistency, and innovation, Paraffin Co. ensures superior performance and reliability in every batch of light slack wax, meeting the diverse needs of its customers worldwide.

Conclusion

In conclusion, light slack wax emerges as a versatile and indispensable material in the textile industry, offering a wide range of benefits and applications. From fabric finishing to yarn lubrication, its unique properties contribute to enhanced performance, efficiency, and quality in textile processing operations. With Paraffin Co. as your trusted partner, you can harness the full potential of light slack wax, optimizing your textile production processes and achieving superior results.

Embark on an illuminating journey through the world of light slack wax with Paraffin Co. as your guide. Explore its diverse applications, specifications, and the invaluable role it plays in enhancing textile production processes.

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us