Paraffin Emulsion & Paraffin Wax: Their Uses, Applications, and Benefits

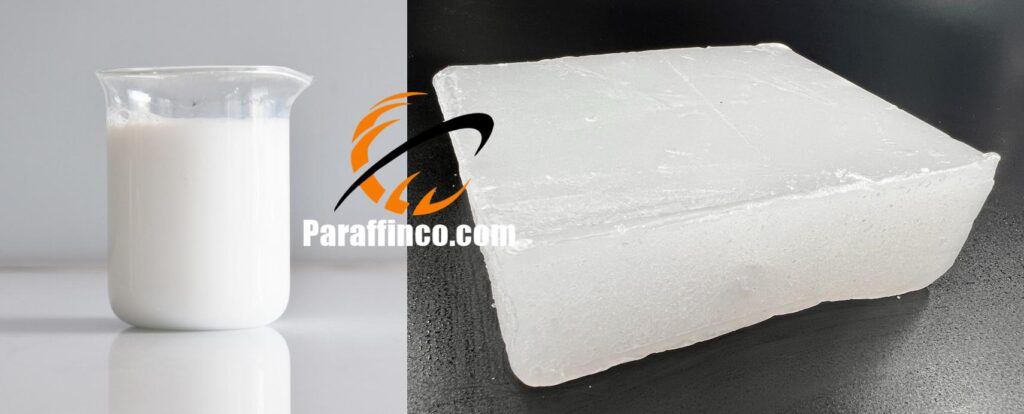

Paraffin Emulsion vs Paraffin Wax, Paraffin wax and paraffin emulsions are two important products derived from paraffin, widely used across various industries. Paraffin Co. Supplier of Paraffin Emulsion and Paraffin Wax, stands as a leading supplier, offering high-quality paraffin wax and paraffin emulsions tailored to meet diverse industrial needs. This comprehensive blog explores the differences, uses, applications, and benefits of paraffin wax and paraffin emulsions, providing an in-depth understanding of these versatile materials.

Understanding Paraffin Emulsion vs Paraffin Wax

What is Paraffin Wax?

Paraffin wax is a white or colorless soft solid derived from petroleum, coal, or oil shale. It consists primarily of saturated hydrocarbons, which are stable molecules composed of hydrogen and carbon atoms. This composition gives paraffin wax its characteristic properties:

- Hydrophobicity: Paraffin wax repels water, making it an excellent barrier material.

- Low Melting Point: The melting point of paraffin wax typically ranges between 46°C and 68°C (115°F to 154°F).

- Plasticity: Paraffin wax is pliable at room temperature and solidifies upon cooling, making it easy to mold and shape.

- Low Reactivity: It is chemically inert under normal conditions, which means it does not react with most chemicals.

Production of Paraffin Wax

The production process of paraffin wax involves several steps:

- Distillation: Crude oil is distilled to separate its components. Paraffin wax is obtained from the heavier fractions.

- Dewaxing: The waxy fraction undergoes a dewaxing process, where it is cooled and filtered to remove oil and impurities.

- Hydrotreating: The wax is treated with hydrogen to remove remaining impurities and improve its color and stability.

- Blending: The refined wax is blended with additives to achieve desired properties for specific applications.

Uses of Paraffin Wax

Paraffin wax is used in various industries, including:

- Candles: Paraffin wax is the primary material used in candle making due to its ability to burn cleanly and consistently.

- Packaging: It is used in packaging to provide a moisture barrier and protect products from humidity.

- Coatings: Paraffin wax is applied as a coating to fruits, vegetables, and cheese to prevent moisture loss and spoilage.

- Cosmetics: It is used in skincare products for its moisturizing properties.

- Industrial Applications: Paraffin wax is used as a lubricant, corrosion inhibitor, and in the production of polishes and sealants.

What is Paraffin Emulsion?

A paraffin emulsion is a stable mixture of paraffin wax, water, and emulsifying agents. It combines the properties of paraffin wax with the versatility of a liquid form, making it easier to apply and integrate into various products. Paraffin emulsions are typically classified based on the size of the paraffin particles they contain:

- Micro Emulsions: Very small paraffin particles, usually less than 100 nanometers.

- Macro Emulsions: Larger paraffin particles, typically in the micrometer range.

Production of Paraffin Emulsion

The production of paraffin emulsion involves:

- Melting: Paraffin wax is melted to a liquid state.

- Emulsification: The melted wax is mixed with water and emulsifying agents. The mixture is subjected to high shear forces to break down the wax into tiny droplets.

- Stabilization: The emulsion is stabilized with surfactants to prevent the wax droplets from coalescing.

Uses of Paraffin Emulsion

Paraffin emulsions have a wide range of uses across different industries:

- Textiles: Used as a finishing agent to impart water repellency and improve fabric texture.

- Paper: Provides a moisture barrier and improves the printability of paper products.

- Leather: Used in the treatment of leather to enhance its water resistance and durability.

- Construction: Employed as a curing agent for concrete, improving its strength and longevity.

- Agriculture: Used as a pesticide carrier and to protect crops from moisture loss.

Paraffin Wax vs. Paraffin Emulsion: Key Differences

While paraffin wax and paraffin emulsions share a common origin, they differ significantly in their form, applications, and benefits:

Form and Composition

- Paraffin Wax: Solid form, consisting of pure paraffin hydrocarbons.

- Paraffin Emulsion: Liquid form, a mixture of paraffin wax, water, and emulsifying agents.

Application Methods

- Paraffin Wax: Applied by melting and coating or molding into shapes.

- Paraffin Emulsion: Applied as a liquid, easily sprayed, or mixed into other liquid formulations.

Use Cases

- Paraffin Wax: Ideal for applications requiring a solid form, such as candles, coatings, and lubricants.

- Paraffin Emulsion: Suitable for applications requiring a liquid form, such as textiles, paper, and concrete treatments.

Benefits

- Paraffin Wax: Provides a robust moisture barrier, is chemically inert, and has excellent moldability.

- Paraffin Emulsion: Easy to apply, versatile, and can be used in formulations where solid wax would be impractical.

Benefits of Using Paraffin Wax

Moisture Barrier

Paraffin wax’s hydrophobic nature makes it an excellent moisture barrier. This property is crucial in packaging applications, where it protects products from humidity and prolongs shelf life.

Thermal Insulation

Paraffin wax’s low thermal conductivity makes it an effective thermal insulator. This property is utilized in various industrial applications, such as in the production of insulation materials.

Chemical Inertness

The chemical inertness of paraffin wax ensures that it does not react with most chemicals, making it a safe and stable material for various applications, including cosmetics and food packaging.

Versatility

Paraffin wax’s ability to be molded and shaped easily makes it versatile for use in candle making, coatings, and even in art and crafts.

Benefits of Using Paraffin Emulsion

Ease of Application

Paraffin emulsion’s liquid form allows for easy application through spraying or mixing with other liquids. This property is particularly beneficial in industrial processes where uniform coating or treatment is required.

Enhanced Properties

The emulsification process can enhance the properties of paraffin, such as improving its adhesion to substrates and its ability to form uniform coatings. This is valuable in applications like textile finishing and paper treatment.

Environmental Benefits

Paraffin emulsions can be formulated to be environmentally friendly, with reduced volatile organic compounds (VOCs) and lower emissions during application. This makes them suitable for use in green manufacturing processes.

Versatility in Formulations

Paraffin emulsions can be easily integrated into various formulations, providing a versatile solution for industries such as agriculture, construction, and personal care products.

Paraffin Co: Your Trusted Supplier

Commitment to Quality

Paraffin Co. Supplier of Paraffin Emulsion and Paraffin Wax, is dedicated to providing high-quality paraffin wax and paraffin emulsions that meet the stringent requirements of various industries. Our products undergo rigorous quality control processes to ensure consistency and reliability.

Customized Solutions

We understand that different applications require specific formulations and properties. Our team of experts works closely with clients to develop customized paraffin wax and emulsion solutions tailored to their needs.

Sustainable Practices

At Paraffin Co., we are committed to sustainability. Our production processes are designed to minimize environmental impact, and we offer eco-friendly paraffin emulsion options to support our clients’ green initiatives.

Technical Support

Our technical support team is always available to assist clients with product selection, application methods, and troubleshooting. We provide comprehensive support to ensure that our clients achieve the best results with our products.

Innovations in Paraffin Wax and Emulsion Applications

Advanced Coatings

Research and development efforts at Paraffin Co. are focused on creating advanced paraffin wax and emulsion coatings with enhanced properties. These include improved adhesion, increased durability, and specialized functionalities such as UV resistance and antimicrobial properties.

Smart Materials

We are exploring the development of smart paraffin materials that can respond to environmental changes. For example, paraffin emulsions that alter their properties in response to temperature or humidity changes, providing adaptive solutions for various applications.

Biodegradable Options

As part of our commitment to sustainability, Paraffin Co. is developing biodegradable paraffin emulsions. These products are designed to break down naturally, reducing environmental impact while maintaining performance standards.

Enhanced Oil Recovery (EOR)

In the oil and gas industry, paraffin emulsions are being investigated for their potential in enhanced oil recovery (EOR) techniques. These emulsions can improve the efficiency of oil extraction processes, making it possible to recover more oil from existing reservoirs.

Conclusion

Paraffin Emulsion vs Paraffin Wax, Paraffin wax and paraffin emulsions are indispensable materials in numerous industries, each offering unique properties and benefits. While paraffin wax is favored for applications requiring a solid form, paraffin emulsions provide the versatility of a liquid form, making them suitable for a wide range of uses.

Paraffin Co., as a leading supplier, is dedicated to providing high-quality paraffin wax and paraffin emulsions tailored to meet the specific needs of various industries. Our commitment to quality, innovation, and sustainability ensures that we remain a trusted partner for companies worldwide.

Whether you need paraffin wax for candle making, coatings, or lubrication, or paraffin emulsion for textile finishing, paper treatment, or concrete curing, Paraffin Co. has the expertise and resources to deliver the right product for your application.

Explore the world of paraffin products with Paraffin Co. and discover how our offerings can enhance your industrial processes and products. Contact us today to learn more about our paraffin wax and paraffin emulsion solutions and how we can support your business needs.

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us